Orcaron Angle Grinder

Junior Year | Spring 2023

Angle grinders are powerful tools meant for jobs ranging from cutting through tough materials to fine-detail sanding. Having a device designed for this range of functions with settings to match each function perfectly will lead to higher levels of efficiency and user satisfaction.

About the Orcaron

The Orcaron is designed to tackle drawbacks and gaps in the leading designs for angle grinders that are readily available on the market. With a large focus on safety and extended usability, the Orcaron combines ideal components and new approaches to control and safety attachments to give the user maximum control while reducing the chances of injury.

Research

Mapping

Primary and secondary Research surrounding the Orcaron consisted of several categories;

– Market Research

– Hands-on teardown of existing product

– Initial User Interviews & Task Analysis

Benchmarking was done between top-rated brands and products and included lower-rated designs. Insights from user reviews, videos, and first-hand experience were taken into account, compared, and used to finalize design decisions surrounding features and interactions such as handles, guards, motors, etc.

Handling & Safety

Common themes surrounding angle grinders usually boil down to control and safety. Users take a risk when they run a blade at hundreds or even thousands of revolutions per minute.

Thankfully, modern designs include handles for user stability and a shield for sparks and debris, including from their own blade (angle grinder blades tend to shatter at the end of their lifespan).

However, through interviews and research, I found that it was common for users to forgo using one or both of these components due to receiving the opposite of the desired effect.

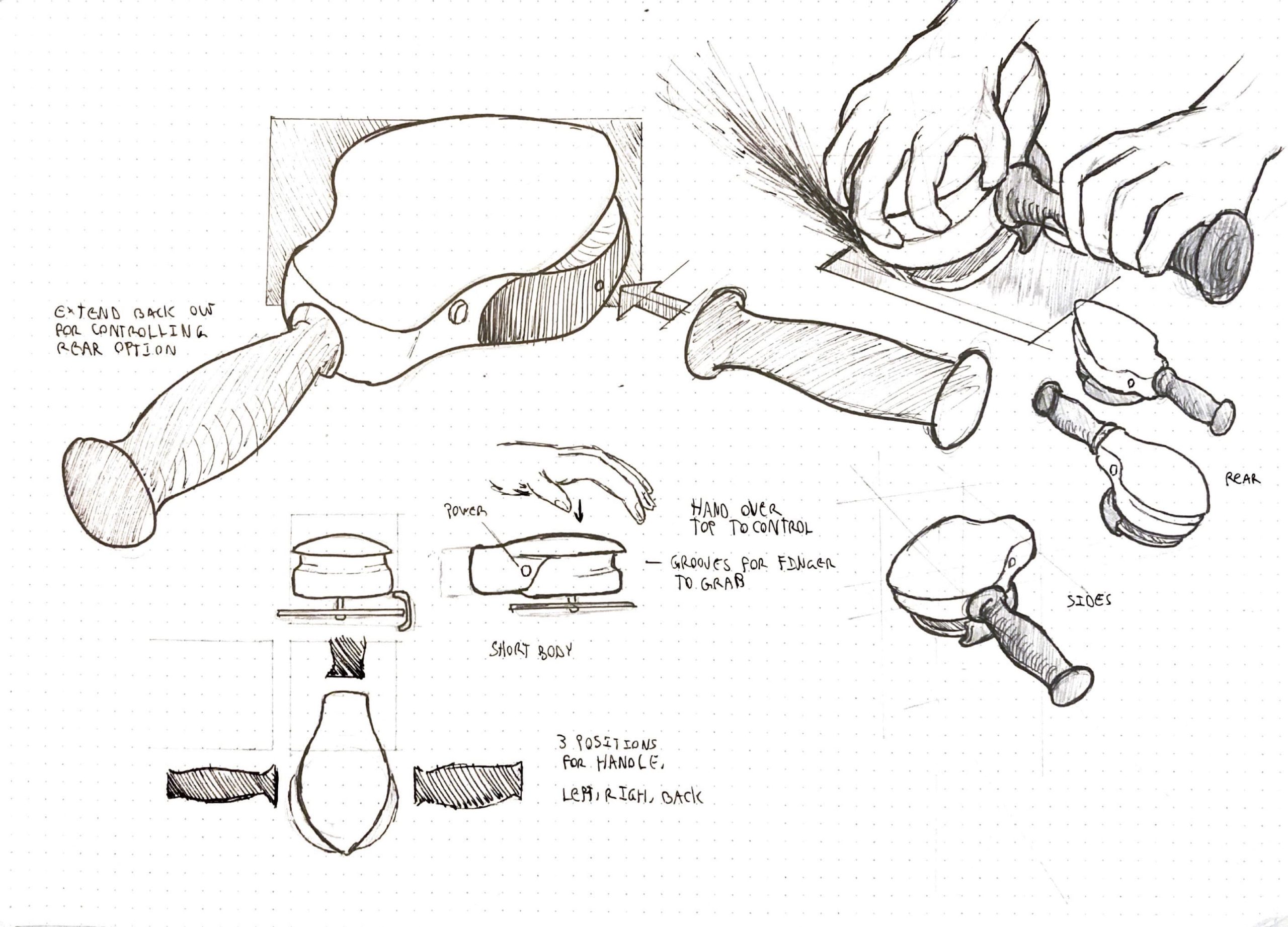

Pictured on the right is one way many users hold their devices, ignoring the handle and placing their hands on the head of the device, much closer to their grind surface and the blade. Most users favored the shield but would continue to decline to utilize this component.

Desired Features

When looking at reviews and interview notes, I compiled a list of favorable features and organized them from most to least.

Among the most favorable were the quick-release guard, a trigger-safety device, and a power lever/paddle.

Other favored features included a trigger-lock mechanism for extended usage, a speed controller, and a spin-lock for attaching the blades.

Items lower on the list included attachments to spindle components and soft-start mechanisms.

Electrical & More

On top of components that the user directly interacts with there is also major importance surrounding what goes into the device, two major areas include topics such as the type of motor and power source.

Many factors go into the motor, such as power output, power usage, heat, wearing down the user, maintenance, and more. Chorded vs. Battery power was also a major debate, with chorded designs benefiting from a much longer usage period and consistent power supply at the cost of mobility. Battery power gives you mobility and range but also creates a limit for the duration of usage.

Movement*

A trend among designs and improvement has been with integrating options with moving parts, such as dimensions, changes (shortening, extending) and feature adjustments. What areas can we explore with angle grinders to bring moving parts to a design in a useful way?

Personas

Tyler Apodaca

Age: 24

Occupation: Home Depot Associate

Hobbies: Woodworking, custom metal art, cooking.

Tool Usage: Angle Grinder & similar tools 3-4 times a week for extended periods. Uses device for wood carving & sanding, metal cutting, finishing, and scale removal.

Needs: A device that gives reliable control for high-detail levels of work and easy setup/usage

How can we design a device to maximize comfort and control on different levels of detail?

John Crouch

Age: 49

Occupation: Bike Repair Technician

Hobbies: Motorcycling, camping, bike upkeep & body-work.

Tool Usage: Heavy and precise tools five to six days a week for repairs and custom work. Sometimes running heavy tools and machines for over 8 hours a day.

Needs: A device that can function for hours while wearing the user down as little as possible

How can we develop an ergonomic and non-damaging device fit for prolonged usage?

Jamie Scherer

Age: 27

Occupation: Graduate Student

Hobbies: Robotics, electrical, mechanical work, arts and crafts, media programming & light effects.

Tool Usage: Rarely uses heavy tools unless doing hands-on work & prototyping with metals and robotics, or helping parents with home repairs.

Needs: A device that is easy to set up and gives control to less skilled and infrequent users

How can we create an inviting design fit for all levels of usage and skill?

Safety Focuses

In the year 2008, Dessert Diamond Industries reported a total of almost

25,000 Injuries

occuring during the usage of angle grinders. The RoSPA even lists angle grinders as the 3rd most dangerous tool, reporting over 5,000 yearly accident cases in the United Kingdom alone.

OSHA statistics studied the injuries related to grinder and saw blade kickback and reported

20% Fatality Rate

along with most of the remaining percent of cases leading to hospital visits. Kickback incidents usually result from operator fatigue but can be attributed to misuse.

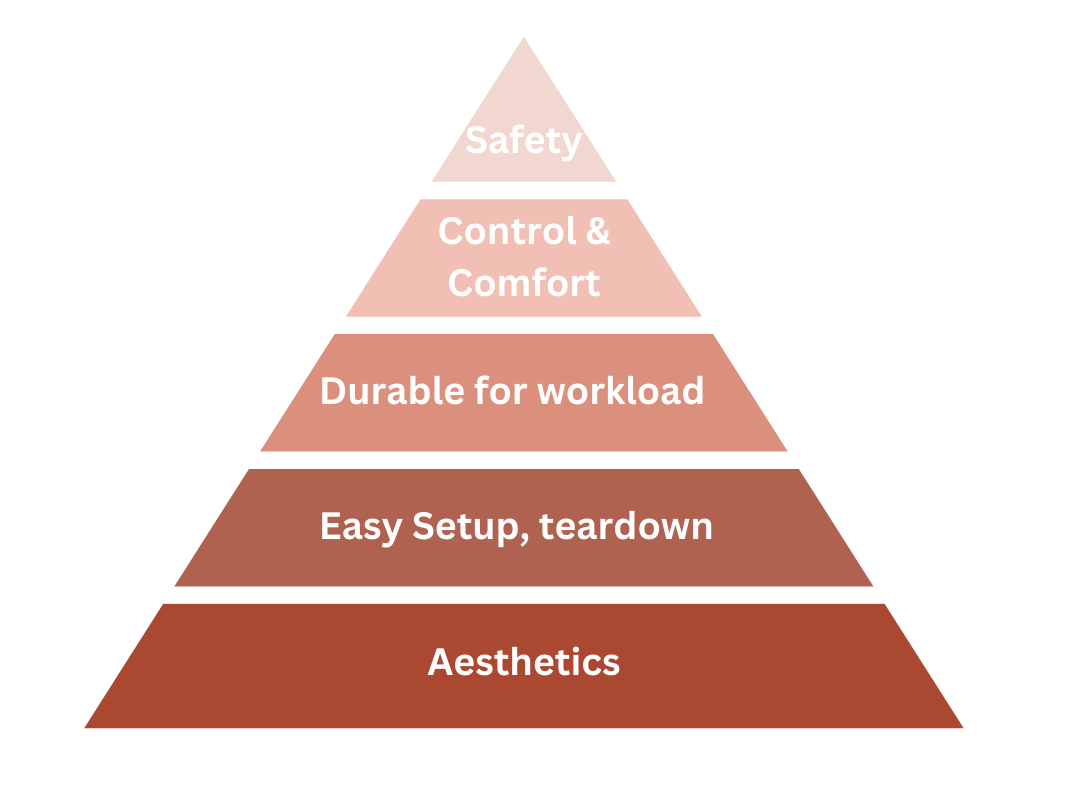

Needs Hierarchy

Safety

Most users noted safety as a top priority, specifically surrounding debris such as sparks, sawdust, and broken grinder blades. Certain approaches to increasing safety include speed controls, light and durable guards, and improved handling.

Comfort

Comfort is adjacent to safety and control, a user’s ability to handle a device for hours without wearing down the user is ideal. Focusing on heat control, kick-back, and even chord management are ideal approaches for maximizing comfort, and improving prolonged usage of these devices.

Control

Many users find themselves using angle grinders for extended periods. Maintaining and maximizing control throughout prolonged usage can be achieved using ergonomic parts and control over individual features such as speed and accessories.

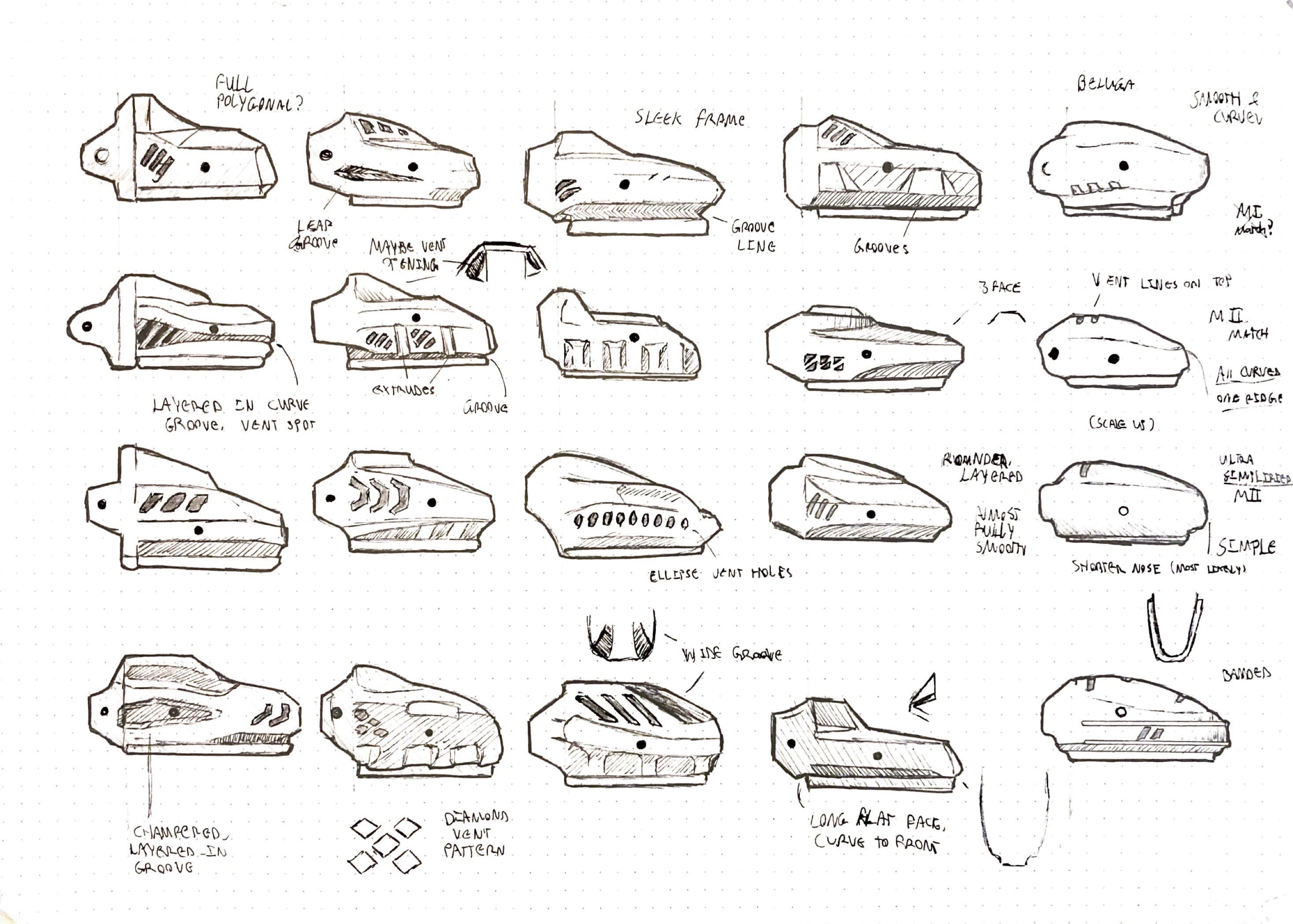

Features and Functions

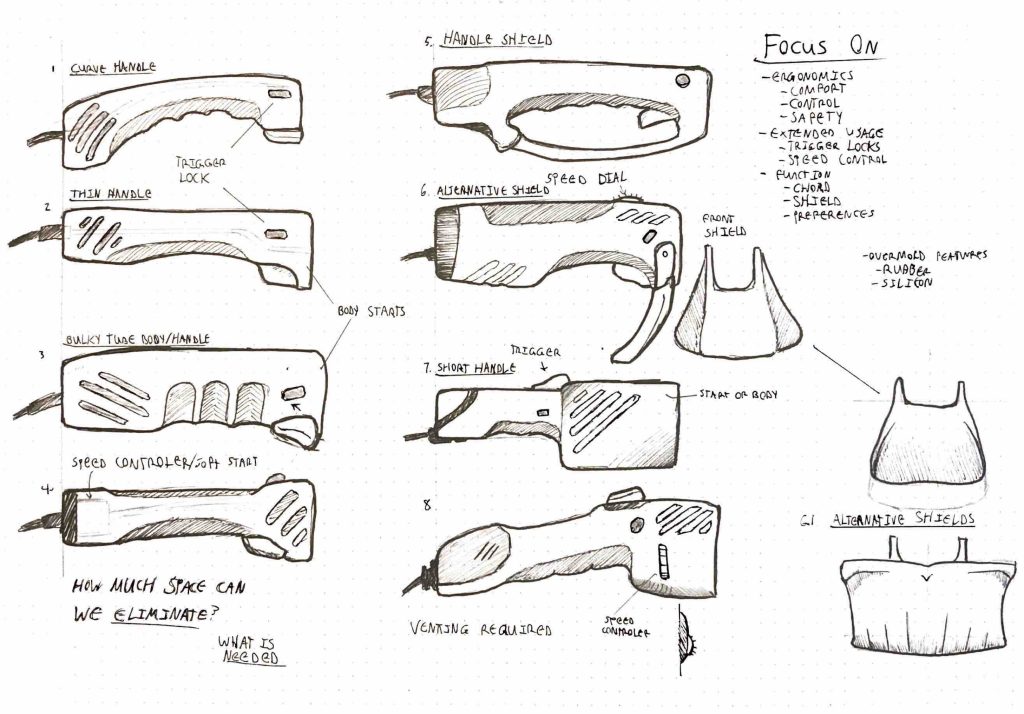

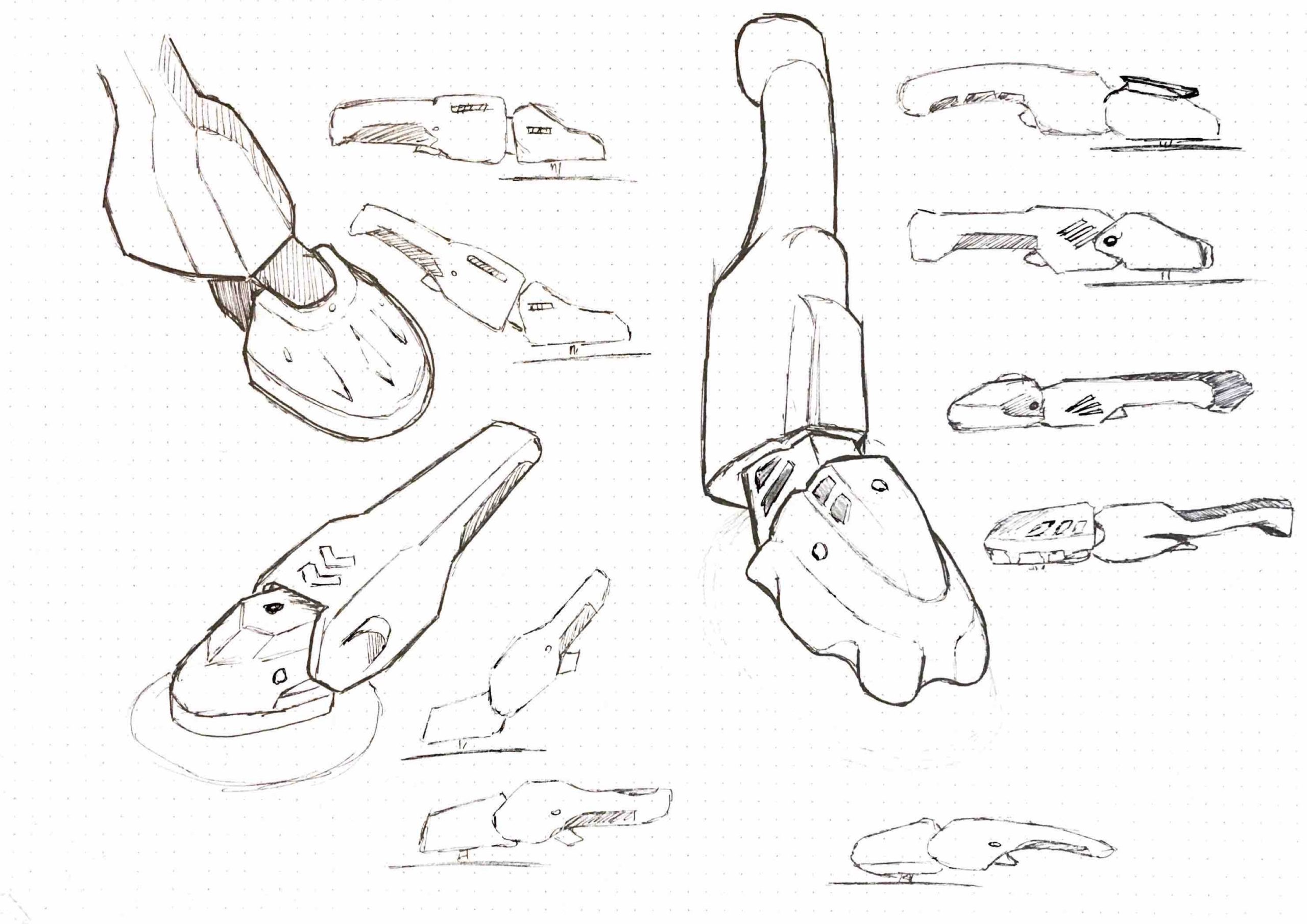

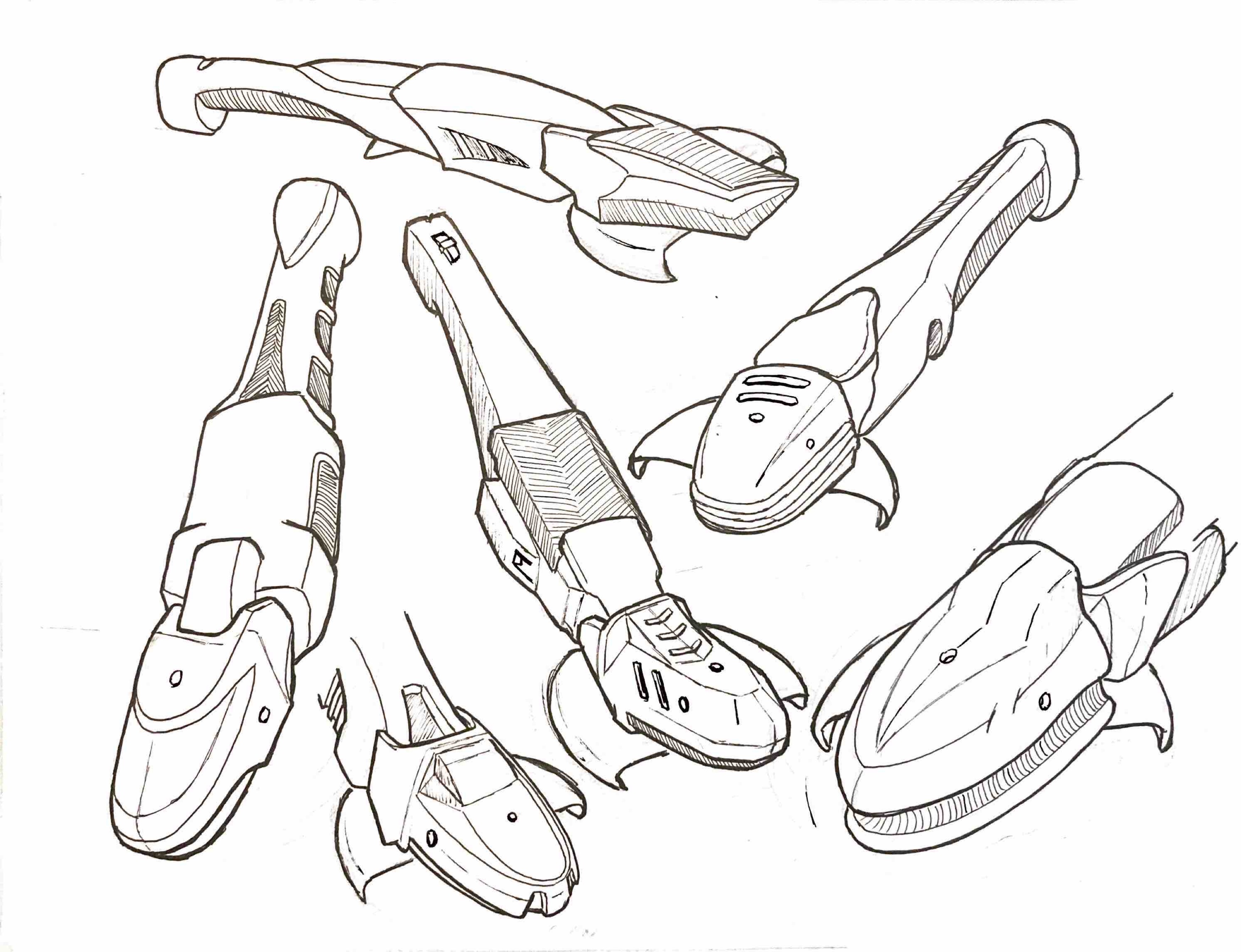

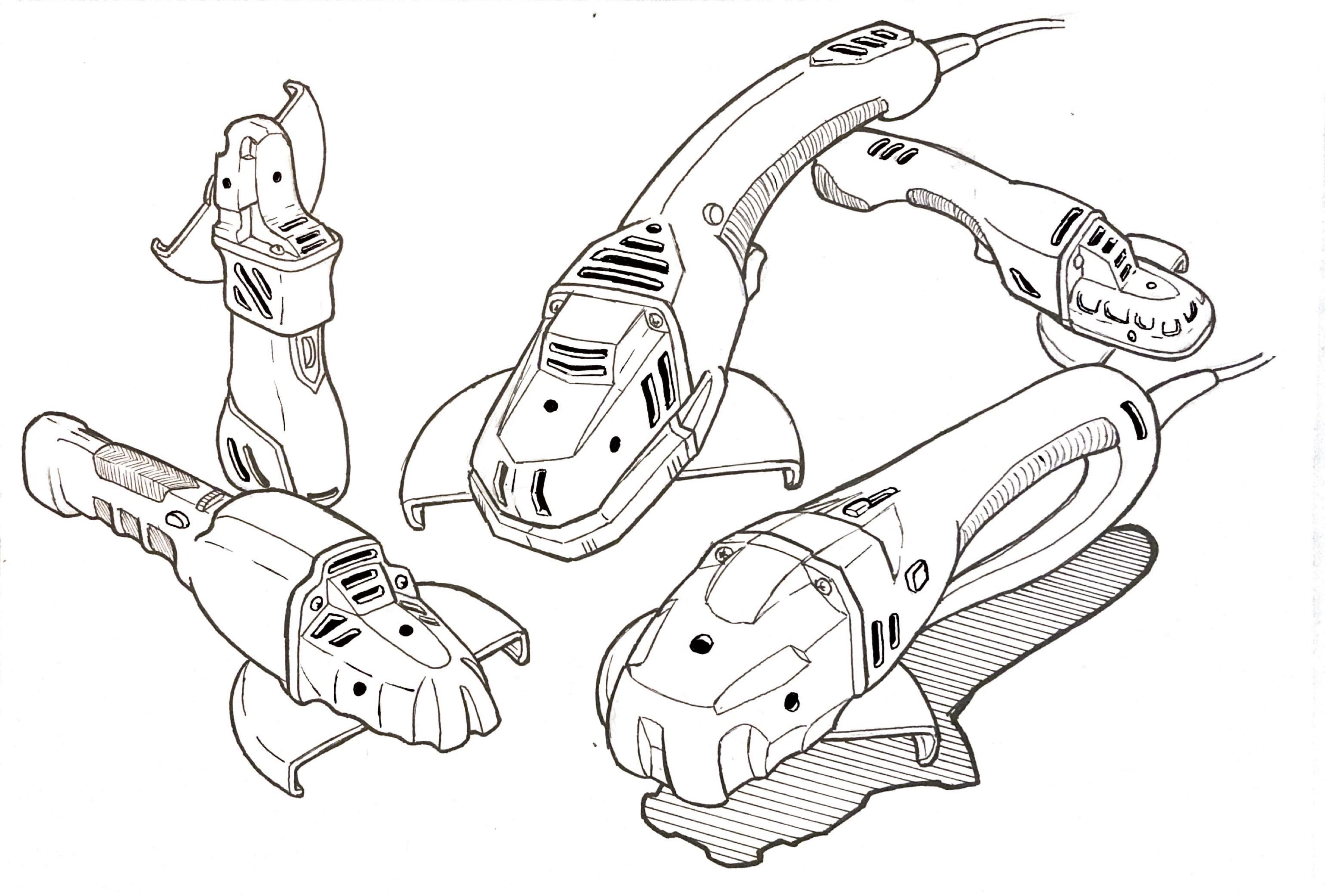

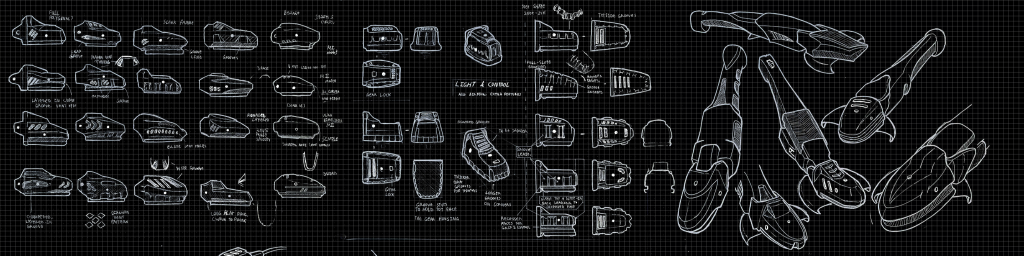

Sleek and powerful

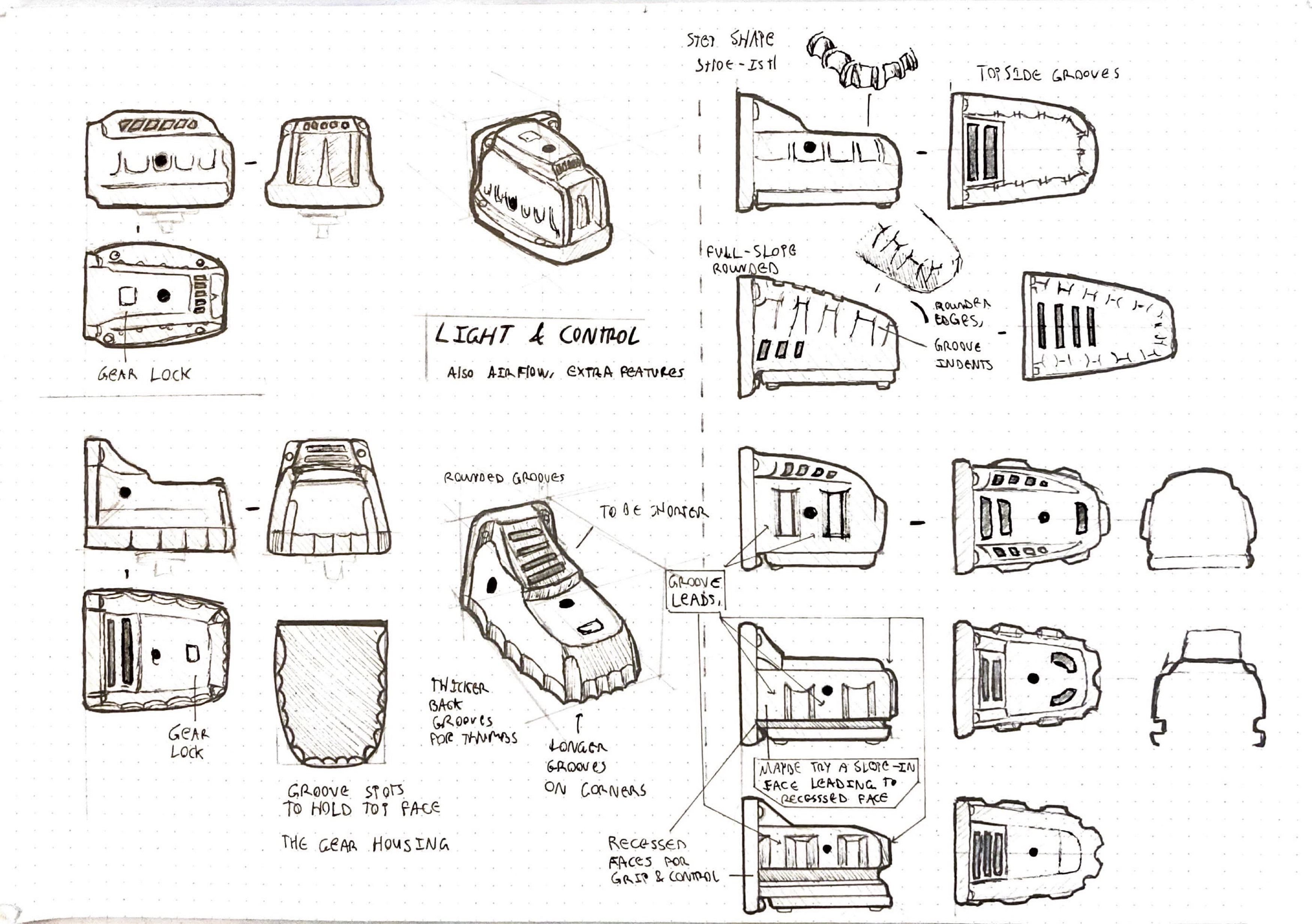

Designs for the device should display attributes such as power and sharpness. A sleek device shows potential for controlled, in-line movement, and chiseled features show durability and strength for all types of usage. The approach taken for sketching ideation was to show power and control embodied in a power tool.

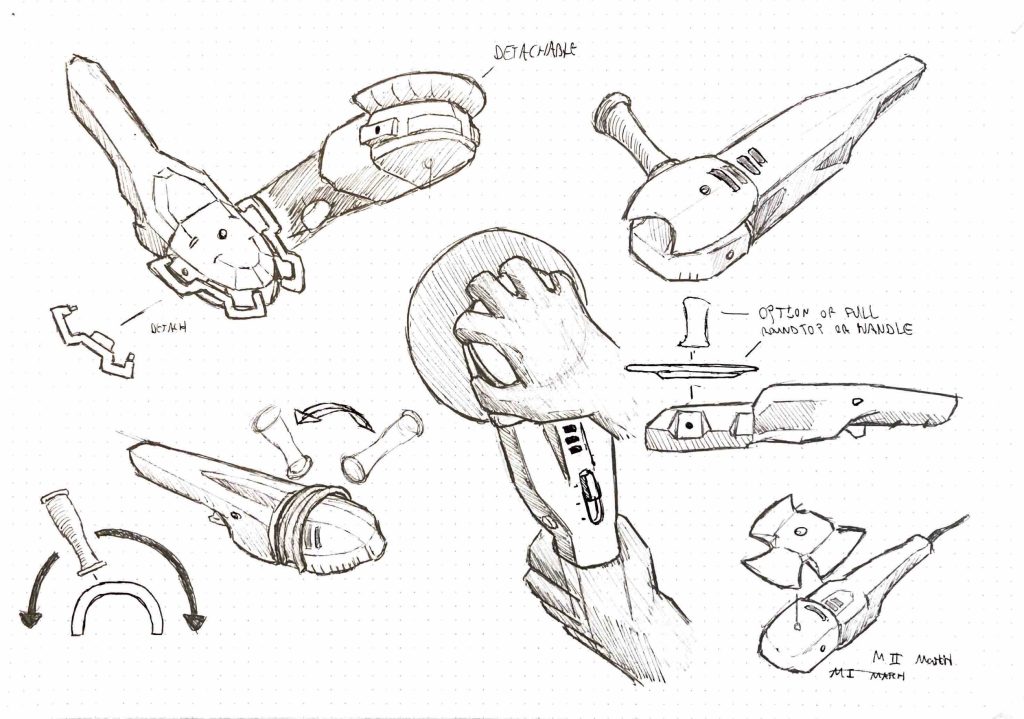

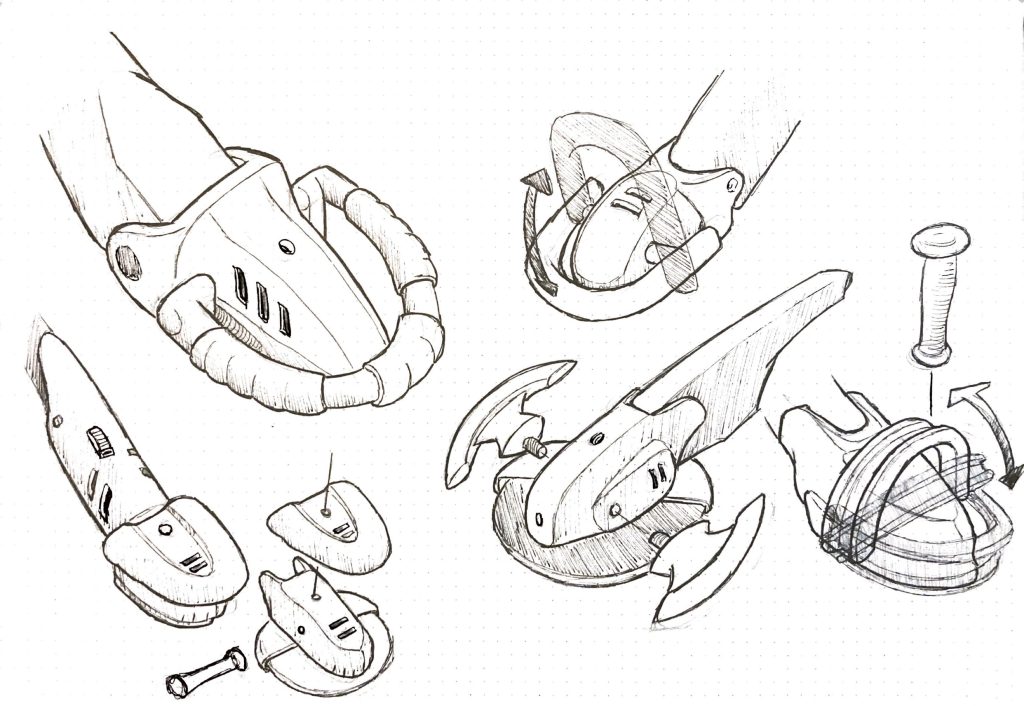

Holding & Handles

When looking at preffered options and disregarded features, details surrounding the handles and ergonomics of angle grinders are under constant contention. What innovations and designs can we explore to maximize safety and control in a way that is not disregarded and is favored by users?

Specialized Features

To stand out as a superior device, what types of features can be included and how would they interact with the body of the device and the device as a whole? Where would they go? What would they look like once integrated? Exploring what features are part of the design and all the interactions that would follow are explored.

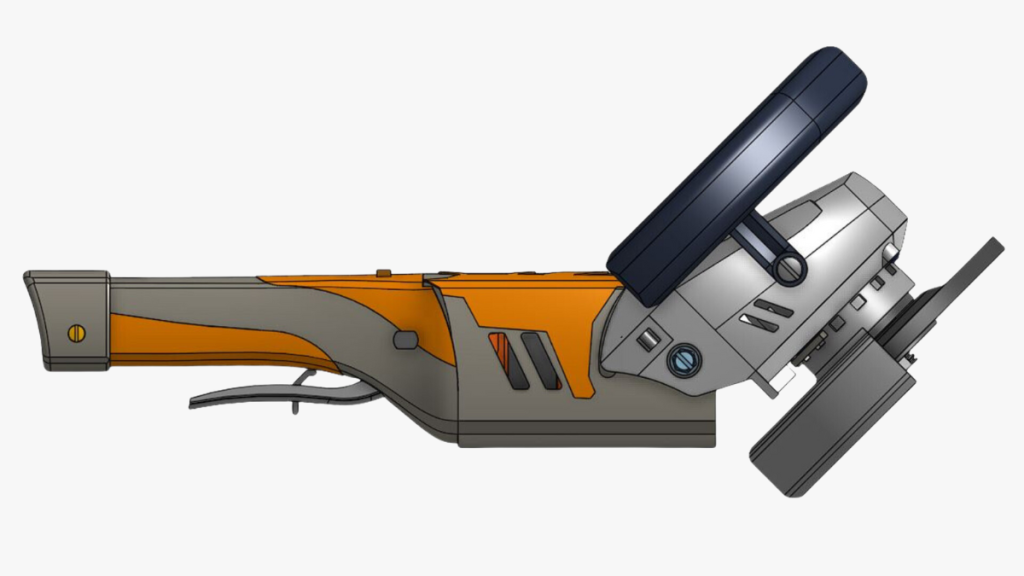

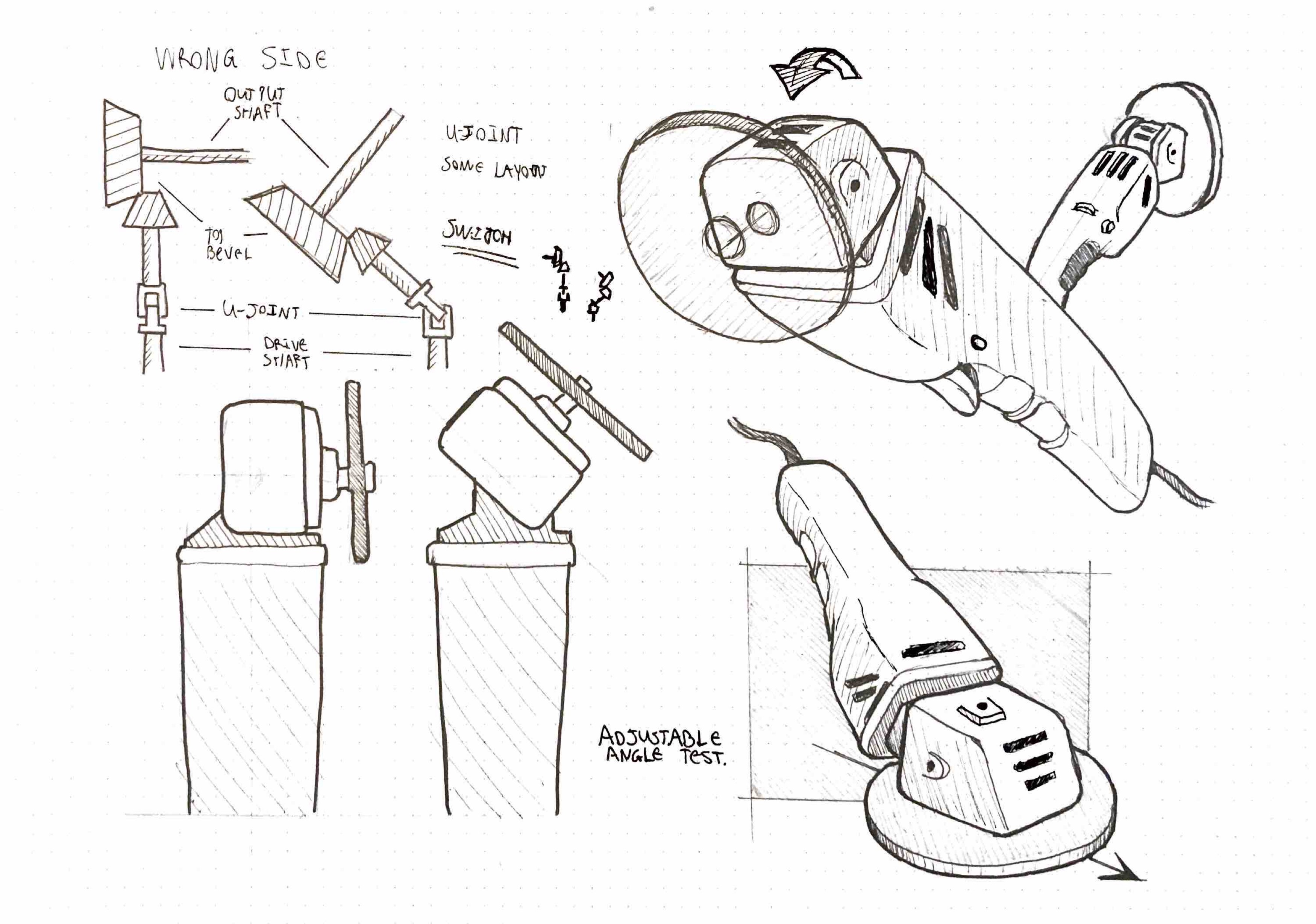

Viable Movement

To create a meaningful design insight that utilizes movement in the body of an angle grinder, what places would give the user a meaningful benefit in performance from an adjustment? A repeated insight from interviews stated adjusted approached in angled from the head could be beneficial.

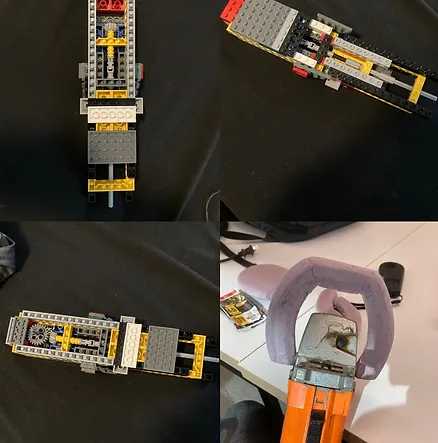

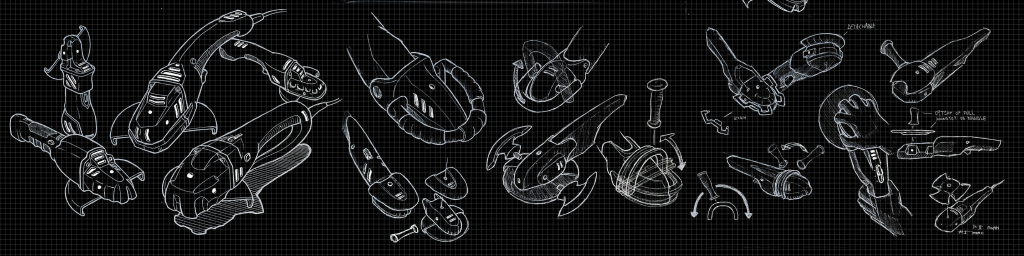

Opening New Angles

An adjustable head angle can give users more control in situations and open more usage types. While exploring how these features would physically interact, I researched and tested ways to make these features a reality, including searching for mechanical details and creating movement tests. In addition to working on the gears and inner mechanisms, I also explored several foam explorations for the body, head, and handles.

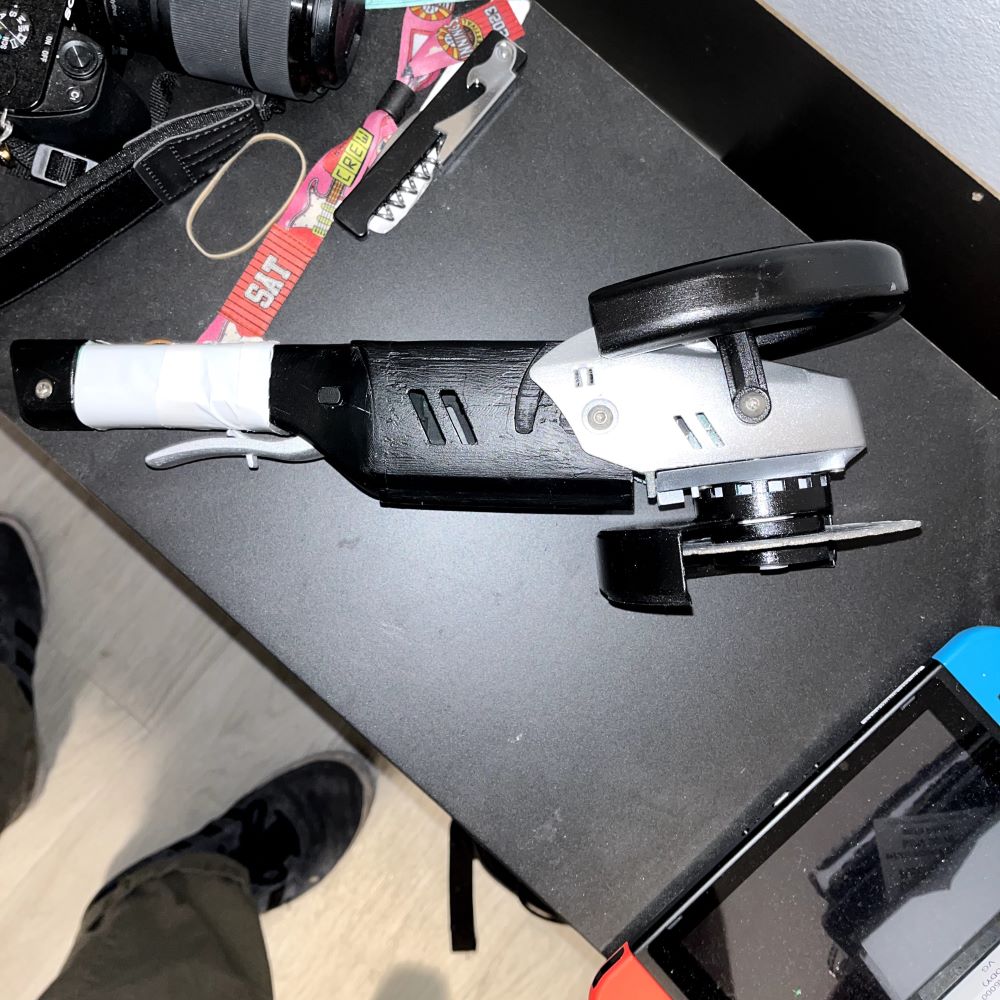

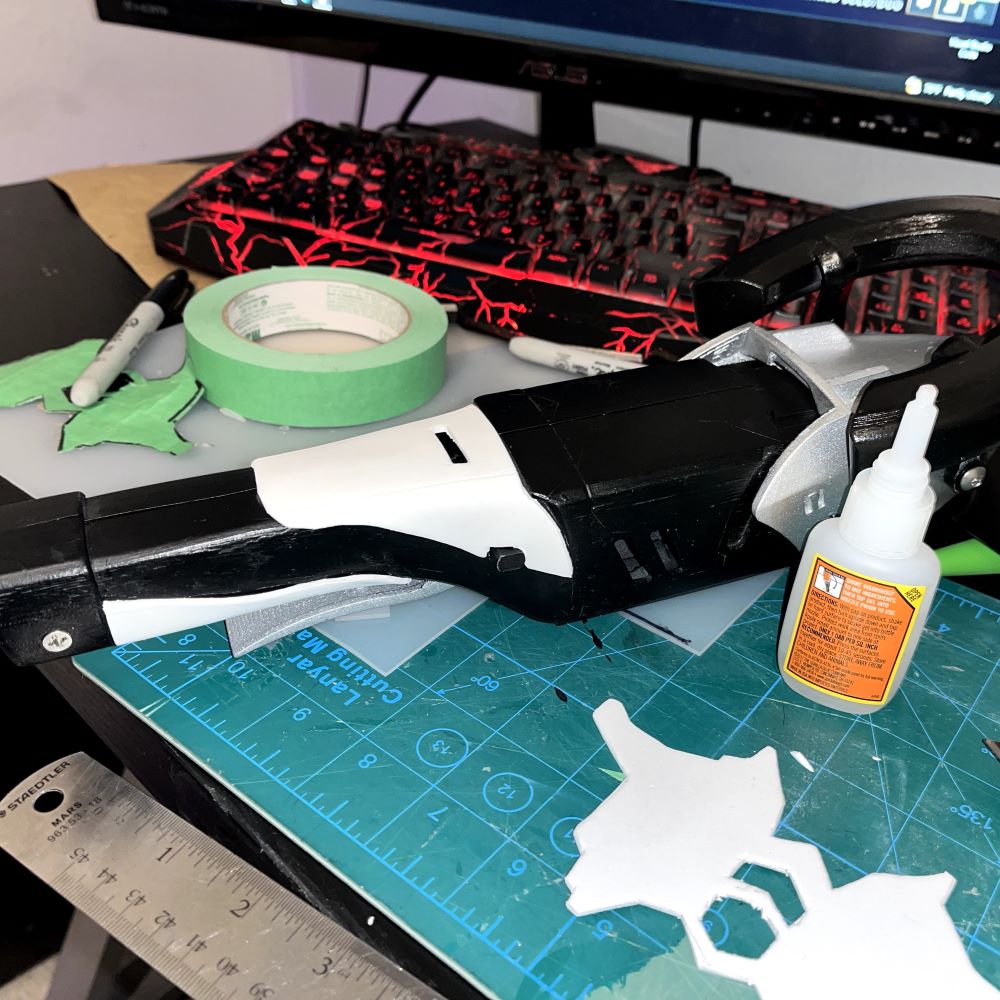

Physical iterations included foam mockups, 3D printed assemblies, and various form & mechanics testings

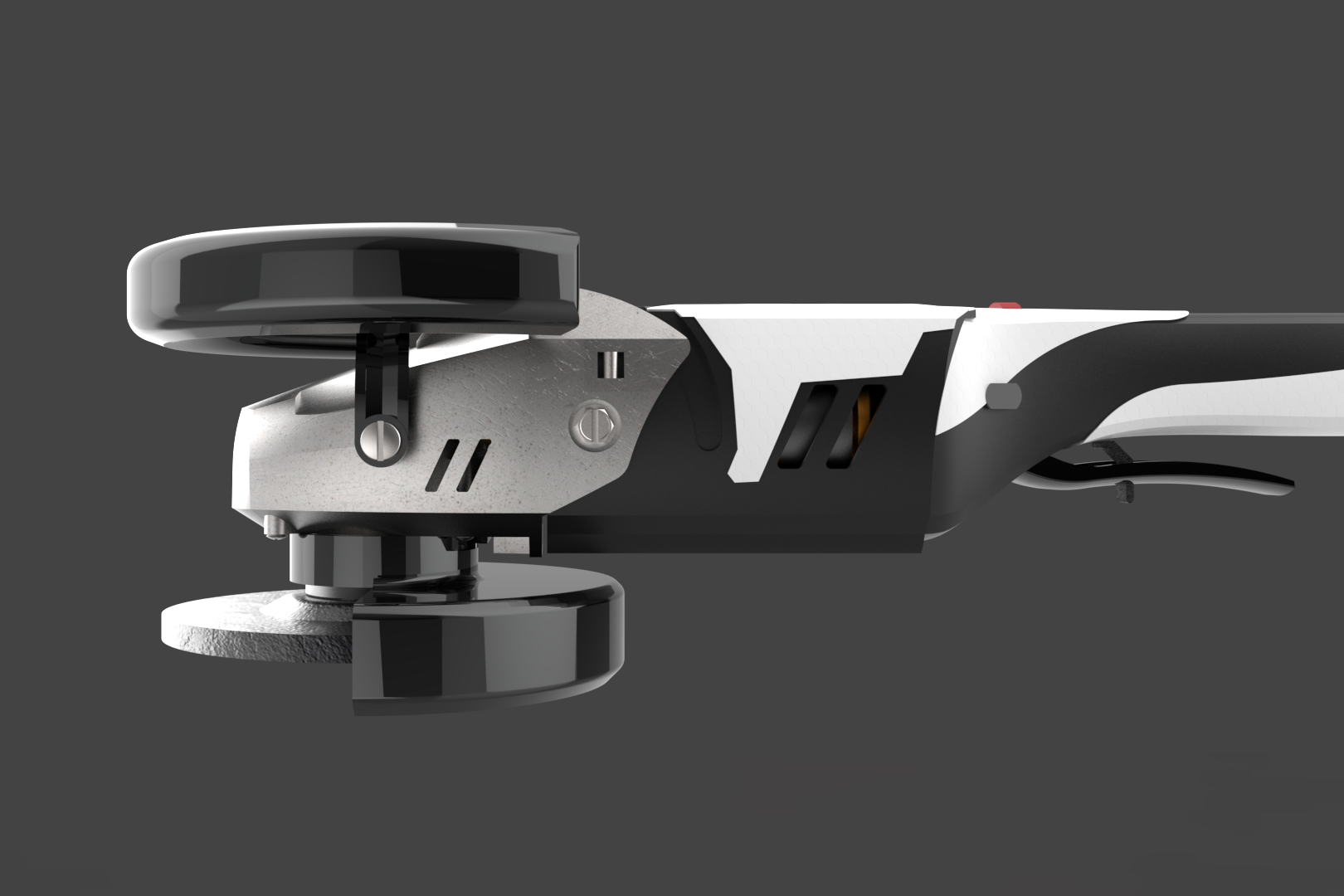

Orcaron

Angle

Grinder

Performance for any project

Made to match your needs of the job without compormising safety.

Adjustable speed means users can use proper and safe settings to cut and sand materials ranging from softer woods to hard stones and even the toughest of metals.

An adjustable angle means users can find more ergonomic approaches and fit into more unusual spaces.

Features & Controls

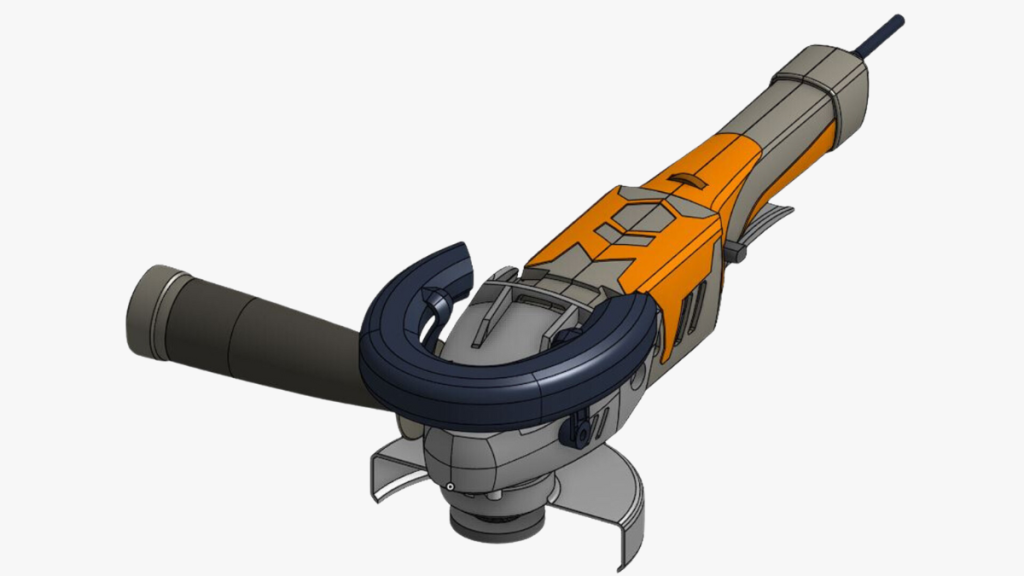

Bringing together the best features for any job

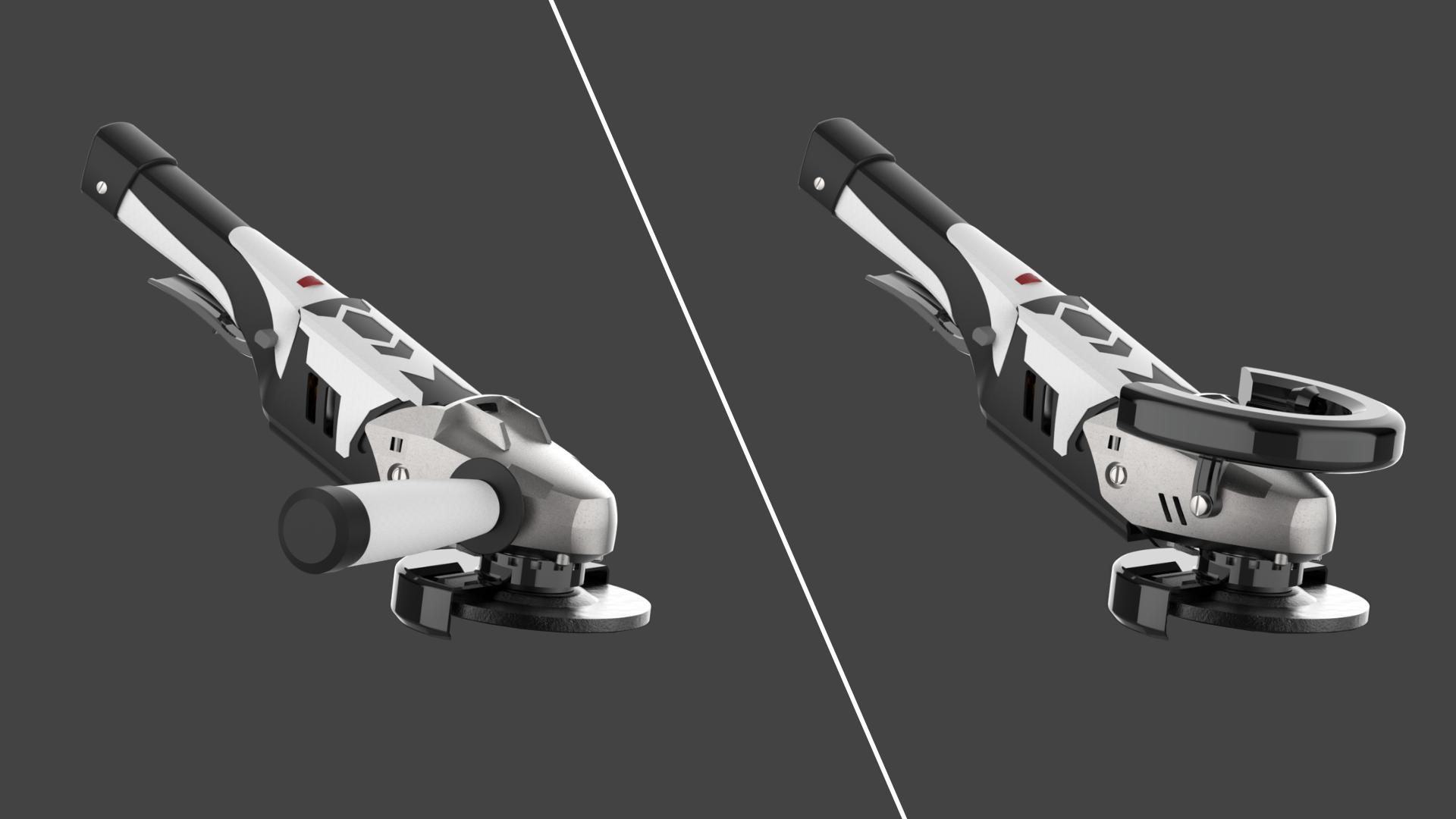

– Trigger Safety to avoid accidents & misfires

– Trigger lock to ease strain on extended usage

– Speed controller to meet different job needs

– Quick Release Guard

– Textured comfort grip

– Multiple hold configurations

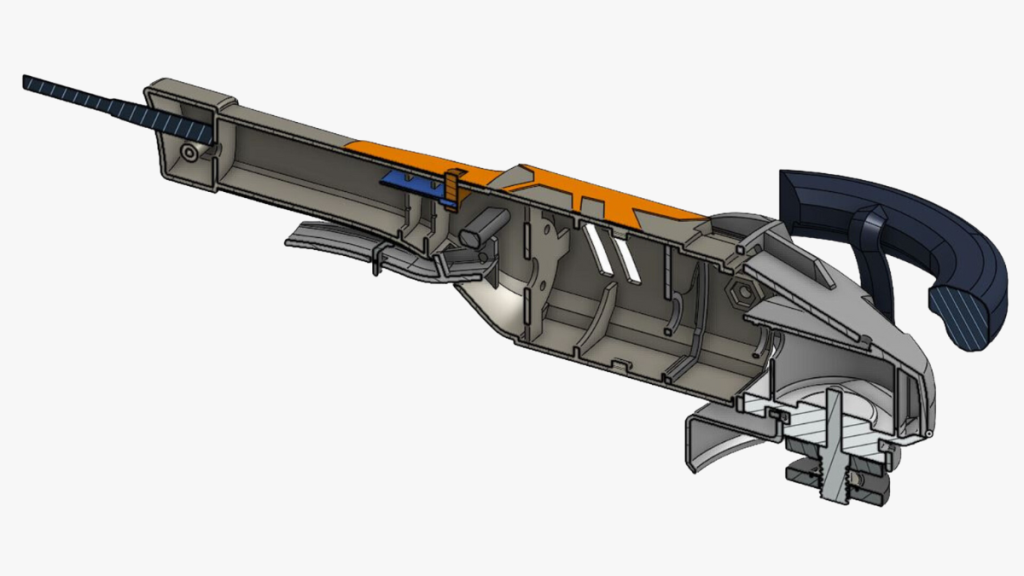

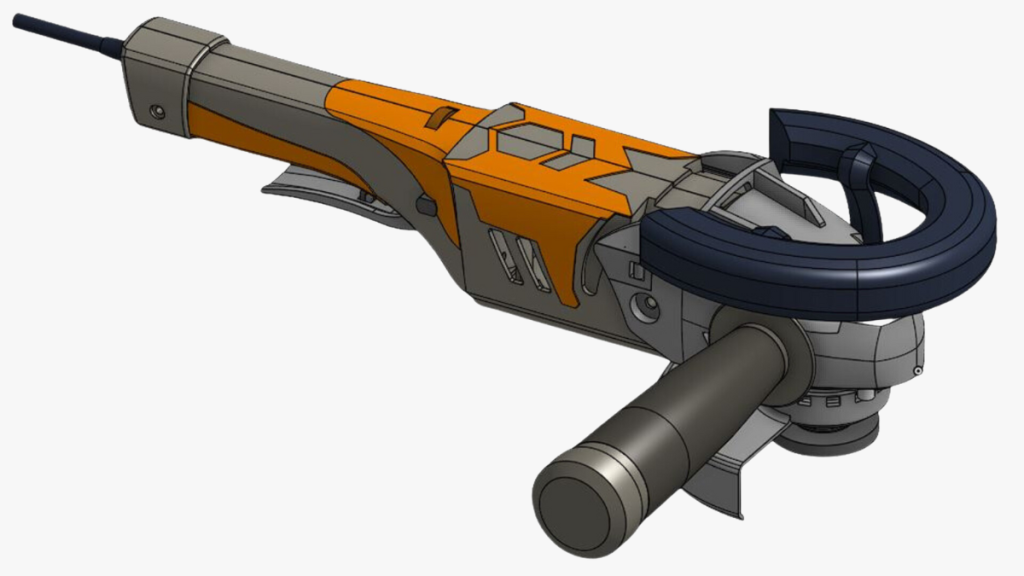

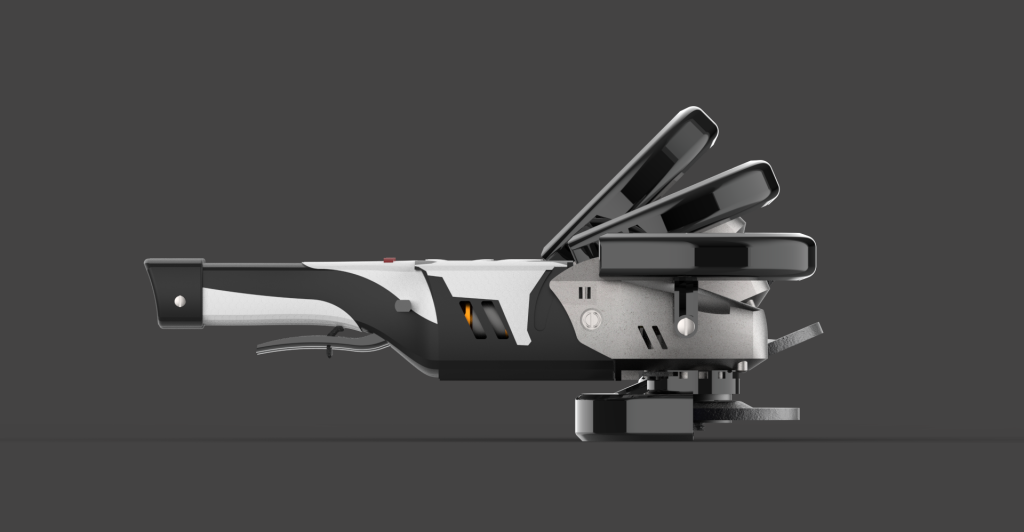

Using a press-release system to adjust the head, the user is given 3 options to adjust their grinder to for their task, 0 degrees (Straight), 22.5 degrees, and 45 degrees.

Pins lock the head into place in order to ensure no unwanted movement.

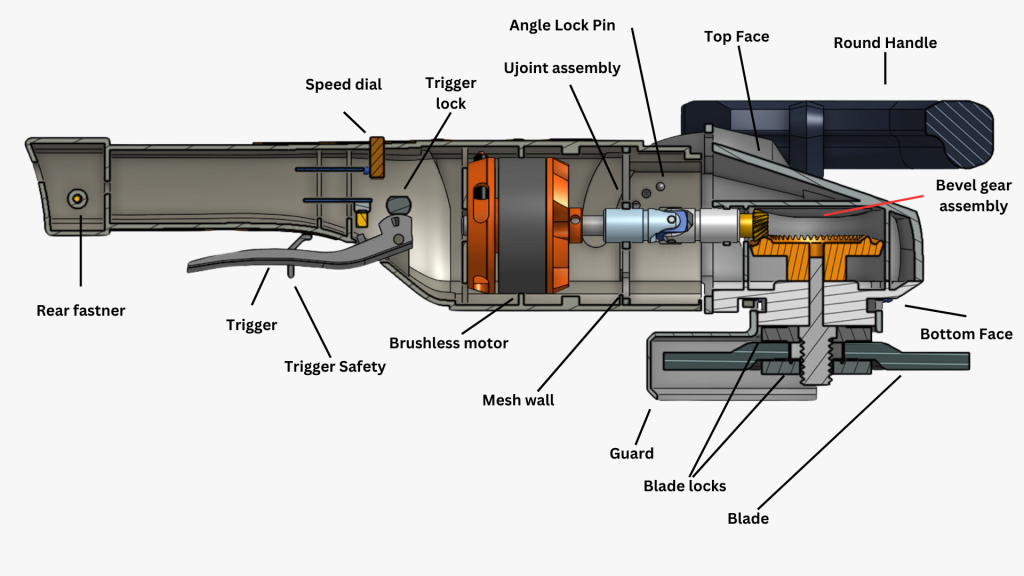

Upgraded Parts

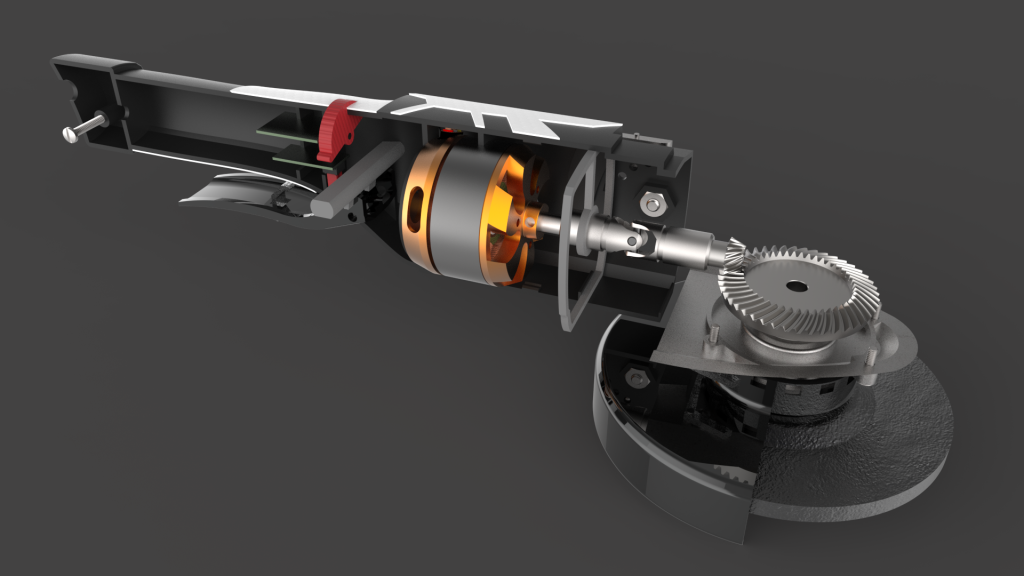

Brushless motor for higher performance, lower maintenance, and lower heat generation during usage.

Universal gear assembly placed in the drive shaft of the motor ahead of the head gears slightly reduces speeds at higher angles but creates an adjustable approach angle for tighter projects and unusual work cases.

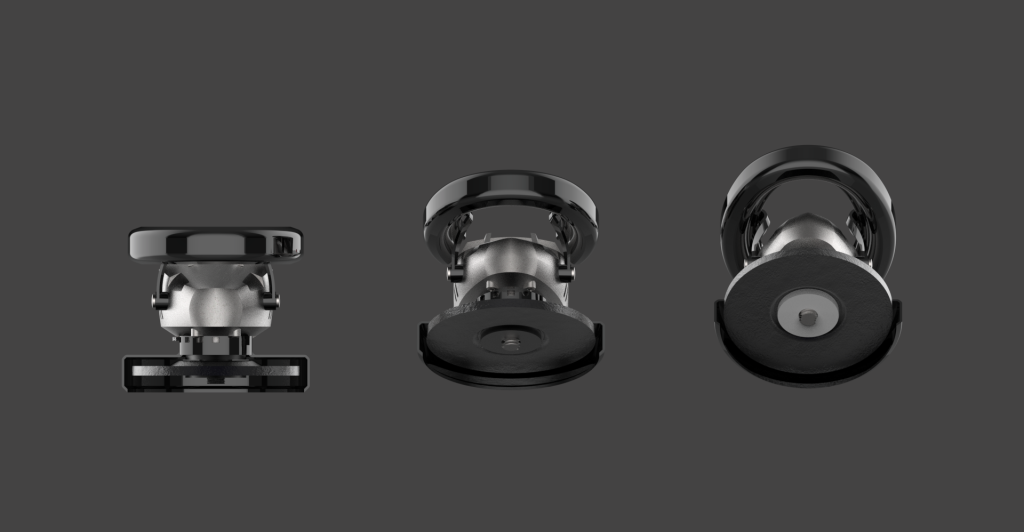

Alternate Handle Options

By providing a familiar pin handle, workers can use a control feature they are most accustomed to. By including an alternative, round handle that moves the control point toward the head of the device while keeping the hands further from the blade, a user who is accustomed to placing their hands at the nose of the device and closer to the blade can achieve a similar placement with less risk.

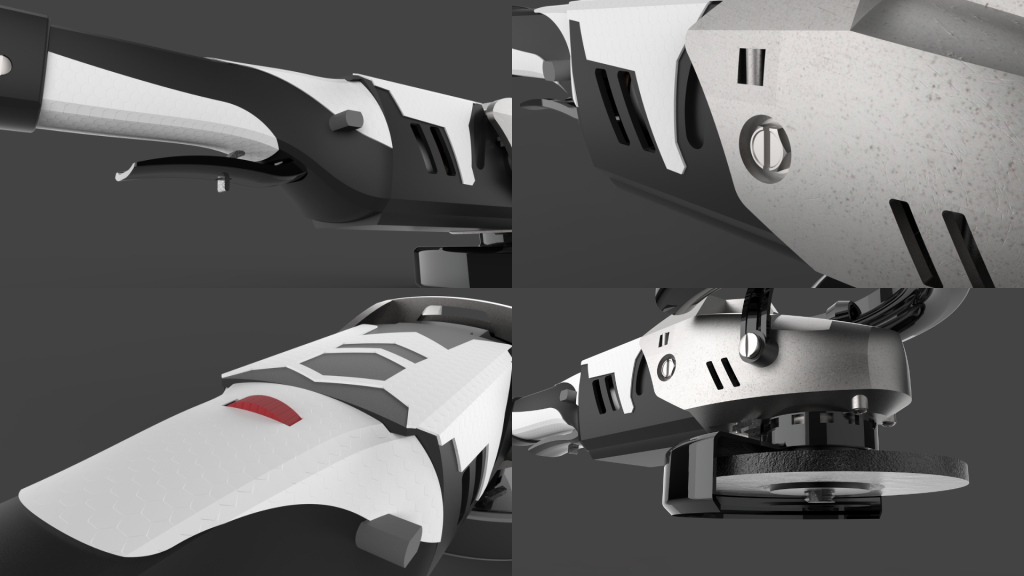

Trigger Safety

Trigger Safety & Trigger Lock features for extended and safe usage and easily accessible.

Comfort & Feel

Textured Silicone and ribbed speed dial for a more comfortable and tactile feel.

Speedy Switches

Quick release guard set for 4.5 inch blades. Quick adjustment to access different angle settings.

Power Type

Chorded power to a brushless motor for longer jobs and less maintenance

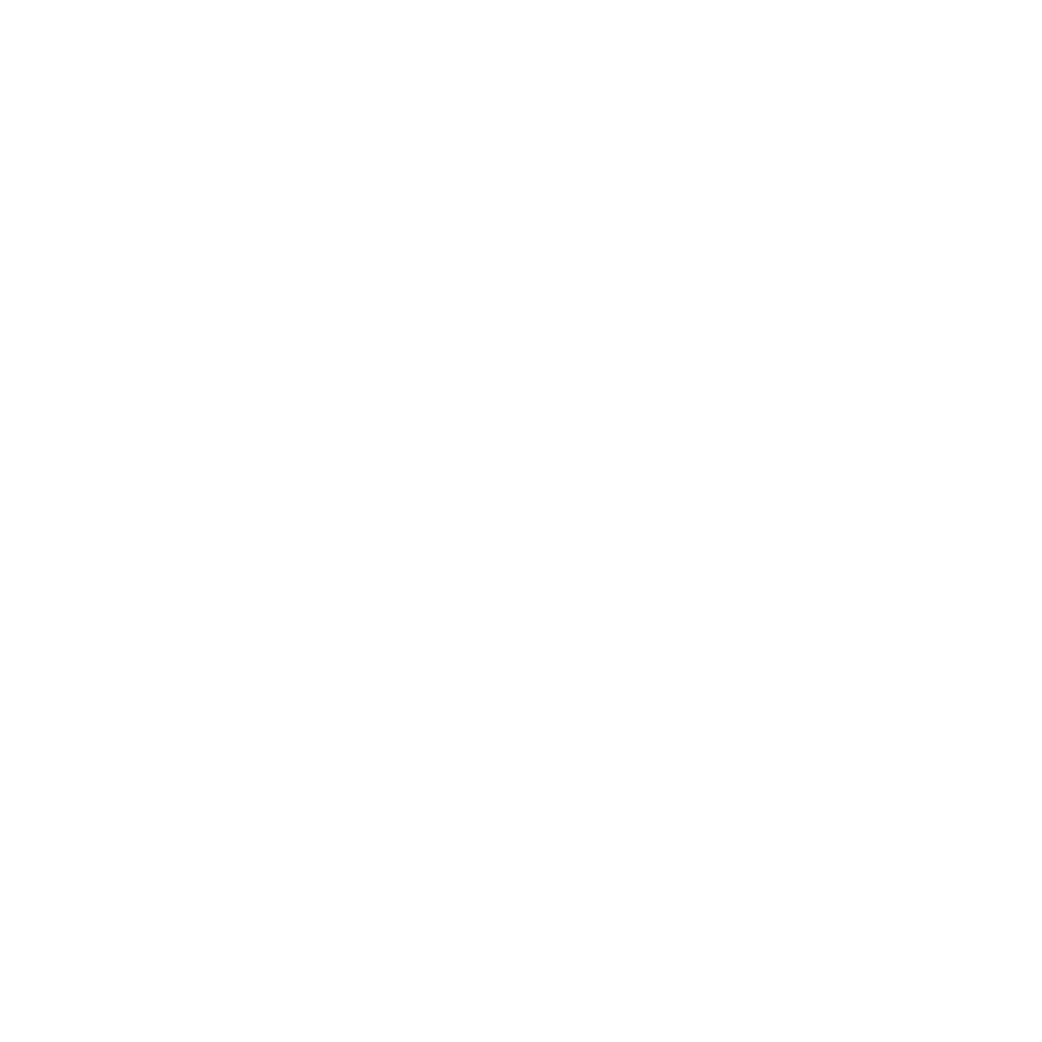

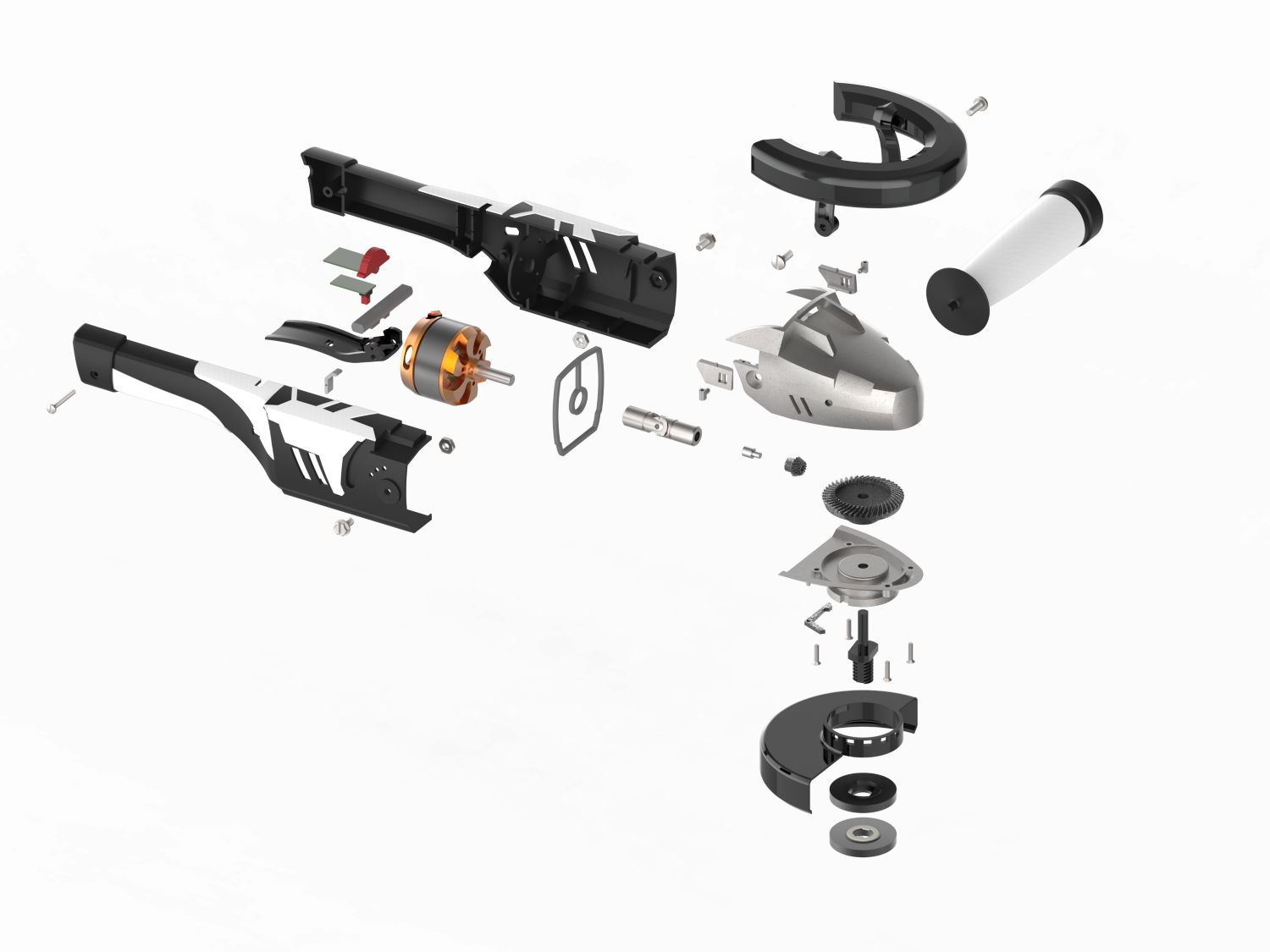

Full Parts Performance

Component inclusion and full assembly, from bevel gears and mounting screws. The body and head were designed with ventilation in mind without compromising this by changing the head angle.

Assembly/disassembly was considered for maintaining the device through repair and replacement of parts such as the motor or universal gear.